Hydraulic Components for Marine & Offshore Applications

Reliability on the Water and Below the Surface

In the marine and offshore industries, equipment must operate reliably in some of the harshest environments on earth. You need hydraulic components that can withstand constant exposure to saltwater, extreme pressures and corrosive conditions. Doering designs and manufactures precision valves, pumps, and manifolds trusted in vessels, offshore platforms, and subsea systems — helping you ensure safety, minimize downtime, and meet demanding industry standards.

Hydraulic Solutions for Marine and Offshore Systems

Doering’s hydraulic product portfolio supports critical functions across marine and offshore operations:

- Directional & Flow Control Valves – deliver precise actuation for winches, cranes, steering, and deck machinery

- Pressure Relief Valves – protect systems from over-pressure in mission-critical equipment

- Cartridge-Style Hand Pumps – compact, reliable backup pumps for emergency or safety-critical systems

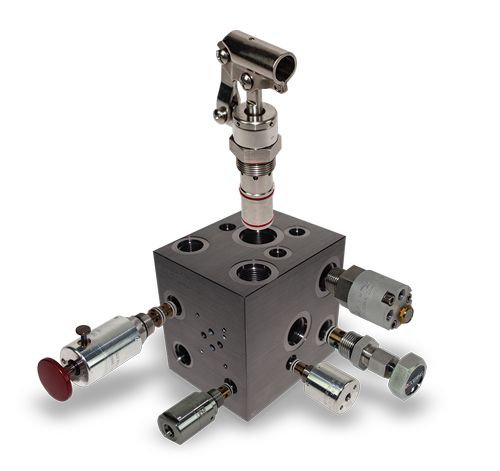

- Custom Manifolds – engineered to integrate multiple functions into compact, corrosion-resistant assemblies

Applications in Marine & Offshore

- Commercial vessels – cargo ships, tankers, fishing fleets, ferries

- Offshore oil & gas platforms – hydraulic power for drilling, riser tensioners and blowout preventers

- Subsea systems – controls for ROVs, subsea valves and wellhead equipment

- Naval and defense vessels – robust, high-reliability hydraulics for demanding missions

- Port equipment – cranes, lifts and bulk handling systems

Built for Harsh Environments

Doering products are engineered for:

- Corrosion resistance in saltwater and subsea applications

- High-pressure performance for deepwater and offshore drilling systems

- Temperature resilience in polar, tropical or variable climates

- Long lifecycle reliability to reduce maintenance and vessel downtime

Why Marine and Offshore OEMs Choose Doering

- Trusted supplier for hydraulic components in marine, offshore, and subsea systems

- Decades of experience working with OEMs and operators in high-risk environments

- Engineering support for system integration, material compatibility, and regulatory compliance

- Manufacturing consistency, backed by documentation and testing required by industry standards

Benefits for Engineers and Supply Chain Managers

- Simplified sourcing with both standard and custom hydraulic solutions

- Reduced downtime with durable components built for marine duty cycles

- Regulatory compliance support with documentation and traceability

- Direct engineering collaboration for tailored system designs

Get Started